Problem:

In the construction industry, creating concrete columns traditionally involved the use of molds constructed from steel and wood. These wooden components were installed within the columns during the casting process, only to be painstakingly removed later. This procedure required workers to enter the column structures, posing significant safety risks and consuming a considerable amount of time.

Solution:

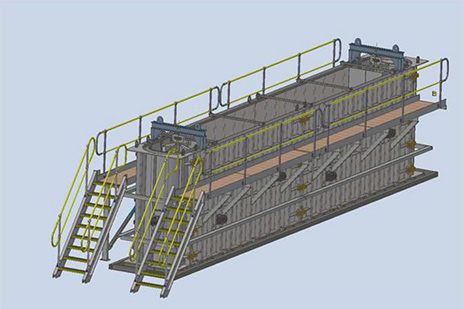

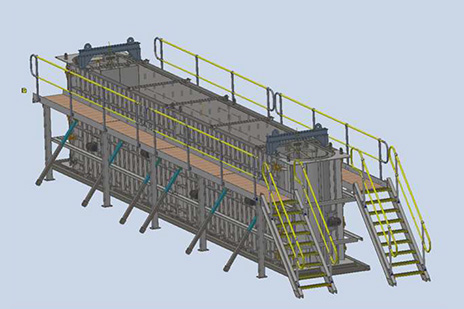

Our engineering team set out to transform this labor-intensive and risky process. We designed a novel column mold constructed entirely of steel, featuring an innovative internal plug system. To release these molds, a crane was simply connected to the plug, which initiated the collapse of the plug and its effortless removal. This breakthrough approach was a game-changer for our client.

The results were astounding. What was once a time-consuming and perilous task now became a streamlined operation, drastically reducing the time required for mold removal. Moreover, the removal process no longer necessitated workers to enter the columns, eliminating high-risk work and enhancing overall safety on the

construction site.

Our steel column molds were not only a time-saver but also a cost-effective solution. The molds were designed for reusability, offering a sustainable and economical option for future column projects. By implementing our innovative design, our client experienced significant time and cost savings while improving worker safety.

This case underscores our commitment to delivering cutting-edge solutions that prioritize efficiency and safety in the construction industry. We take pride in our ability to transform traditional practices into innovative processes that benefit our clients and their projects.